- Decorative Concrete Overlays Home

- Floor Overlay Cost

- Types of Overlays

- Comparison Chart of Overlay Systems: Which is Best for Your Project?

- Getting Surfaces Ready for an Overlay

- When to Use a Cement-Based Polymer Overlay

- Concrete Resurfacing

- Concrete Underlayments: Tips for priming the substrate

- Design Ideas for Concrete Overlays

- Concrete Coloring Methods

- Stamped Concrete Patterns and Designs

- Concrete Overlays Color Chart

- Applying Decorative Stencils

- Polishable Overlays

- Maintaining Resurfaced Concrete

- Routine Maintenance for Overlays

- Other Resources

- Concrete Contractors: Find Concrete Overlays Products and Suppliers

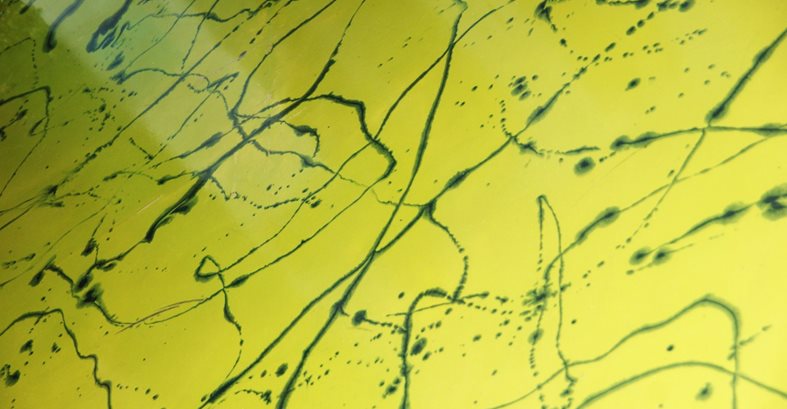

“Wow” Factor Flooring

A metallic coating provides unique flooring for a spirit and wine parlorProject submitted by Thomas Villasana, A-Plus Concrete Construction, Fresno, Calif.

Thomas Villasana of A-Plus Concrete Construction sent in this project completed for Cuvée, a spirit and wine parlor in Fresno, CA. “The owners wanted something different than a regular concrete floor,” says Villasana. They had seen metallic flooring online and sought out A-Plus Concrete to see if it was something they could do. “We do a lot of floor epoxies but this was our first time using Westcoat’s Liquid Dazzle,” he says, “it was a challenge, but with the right personnel it can be done.”

Surface preparation was a very important part of this job. “There was a lot of prep to the existing concrete floor due to the different flooring that had been applied throughout the building. We made sure not to leave any stone unturned as far as prep,” Villasana recalls. With more than 1400 s.f. of carpet, tile and linoleum to remove, the prep work took over three days to complete. First, the concrete was ground with a dual grinding floor machine and cracks were repaired. Once the cracks were filled, the floor was ground flush and cleaned with degreaser and tri-sodium phosphate.

Prior to applying the Liquid Dazzle, a primer coat was applied to the floor. Next, the Liquid Dazzle was applied by a single installer to get consistency of the effects. The colors used were chartreuse for the main floor and marine for the dazzle effects. “We found that heat plays an important part with the Liquid Dazzle, the warmer the temperature the more movement you get,” says Villasana. Twenty four hours later a topcoat was applied.

Villasana and the owners of Cuvée were happy with the results. “We hope to keep putting this product down as our best flooring. If you want a durable epoxy floor with lots of wow factor this is the product,” he says. He would like to thank Bill Cummings from Legacy Construction, Mark Krusser from Constar Supply, Mike Mullex from Westcoat and Jose and Dan from the House of Concrete for their involvement and support.

Materials used

Crack repair: Roadware 10 Minute Concrete Mender

Floor primer: Westcoat, EC-11 Water-Based Epoxy

Decorative epoxy coating: Westcoat, Liquid Dazzle

Finish: Westcoat, EC-95 Polyurethane Topcoat

Concrete Contractor

Thomas Villasana

A-Plus Concrete Construction, Fresno, CA

www.aplusconcreteconst.net

General Contractor

Bill Cummings

Legacy Construction, Fresno, CA

www.lcfresno.com

Submit Your Own Project Photos

Learn more about using concrete for brewery floors